Smart door locks surface treatment refers to the processes used to modify the surface of a material in order to improve its appearance, durability, or other properties. There are many different types of surface treatments that can be applied to smart door locks, depending on the specific material and desired properties.

For example, a smart door lock made of metal may be treated with a coating to prevent rust or improve its appearance. Smart door locks spare parts made of plastic may be treated with a UV-resistant coating to prevent fading or yellowing. Other surface treatments that may be applied to smart door locks include oxidization, electroplating, and powder coating.

Here below this blog will introduce some common use ways for door locks surface treatment.

Anodic oxidation

Anodic oxidation is a process used to create a hard, protective coating on metal surfaces. In the context of door locks, it can be used to improve the durability and corrosion resistance of the lock components, such as the lock surface and key. The process involves immersing the metal parts in an electrolytic solution and applying a current to the metal. This causes the surface of the metal to oxidize, creating a thin, hard coating. The process can be repeated multiple times to build up a thicker coating. Anodic oxidation can be used to improve the performance of door locks, can provide increased resistance to wear and corrosion, it is important to ensure that the coating is properly applied and that it does not affect the lock’s ability to function properly.

In order to use anodic oxidation on door locks, the locks would need to be disassembled and cleaned, then placed in the electrolyte solution and connected to a power source. The process would need to be carefully controlled to ensure that the correct thickness of oxide is formed on the surface of the lock, and that the lock is not damaged during the process.

Process Flow

Single color/ gradient color: polishing/sandblasting/brushing → oil removal → anodizing → neutralization → dyeing → sealing → drying

Two-color: ① polishing/sandblasting/brushing → oil removal → masking → anodizing 1 → anodizing 2 → sealing hole → drying

② polishing/sandblasting/brushing → oil removal → anodizing 1 → laser engraving → anodizing 2 → sealing hole → drying

Technical Features

- Enhanced strength

- Realization of any color except white

- Realization of nickel-free sealing, meeting the requirements of Europe, the United States and other countries for nickel-free

Technical difficulties and improvement points

The level of anodic oxidation yield is related to the cost of the final product. The key point to improve the oxidation yield is the right amount of oxidizer, the right temperature and current density, which requires smart door locks structural parts manufacturers to explore and seek breakthroughs in the production process.

Smart Door Locks Recommendation: Our CNC hotel door locks and Bluetooth digital door locks

Electrophoresis

Electrophoresis surface treatment is a process that uses an electric current to apply a coating to a surface. It can use for stainless steel, aluminum metal etc. material metal surfaces. It can make the locks be different colors, and keep its metal shining, at the same time keep good anti-corrosion properties.

Process Flow

Pr-treatment → electroscopes → drying

Advantages

1: With rich colors;

2: No metallic texture, can be combined with sandblasting, polishing, brushing, etc.;

3: Processing in liquid environment, can achieve complex structure of surface treatment;

4: With mature process, can mass production.

Disadvantages

It with general ability to cover defects, so die castings parts do electroscopes need good pre-treatment before treatment.

Micro-arc oxidation

Micro-arc oxidation is the process of applying high voltage in an electrolyte solution (generally a weak alkaline solution) to generate a vitrified surface film layer, which is the result of the synergistic effect of physical discharge and electrochemical oxidation.

Micro-arc oxidation (MAO) is used in door locks because it can create a hard, corrosion-resistant coating on metal surfaces. The coating is created by applying a high voltage, low current electrical discharge to the metal surface, which causes it to oxidize. This process can be used to improve the durability and longevity of door locks, as the coating can protect the metal from wear and tear, as well as from rust and corrosion. Additionally, MAO can improve the appearance of the door lock, as the coating can have a smooth, glossy finish.

Process flow

Pretreatment → hot water washing → MAO → drying

Advantages

1: With ceramic texture and dull appearance, no high-gloss products, but with delicate feel and anti-fingerprint;

2: With a wide range of substrates: Al, Ti, Zn, Zr, Mg, Nb, and their alloys, etc.;

3: Simple pre-treatment, product corrosion resistance, excellent weather resistance, good heat dissipation performance.

Disadvantages

the current color is restricted, only black, gray and other more mature, some bright colors are difficult to achieve;

and cost is high for high power consumption, is one of the highest cost of surface treatment ways.

PVD Vacuum Deposition

Physical vapor deposition, or PVD, is a process that involves the deposition of a thin film of material onto a substrate.

PVD coatings be used to improve the durability of the lock itself, by providing a protective barrier against corrosion or wear. Overall the PVD can be used to improve the performance and longevity of door locks.

Process flow

PVD pre-cleaning→vacuuming in the furnace→target washing and ion cleaning→coating→coating finished, cooling out of the furnace→post-treatment (polishing, AFP)

Technology features: PVD (Physical Vapor Deposition) can be used to coat metal surfaces with high hardness and high wear resistance metal-ceramic decorative coatings

Electroplating

Electroplating is a process used to coat metal surfaces with a thin layer of another metal using electricity. In the case of door locks, electroplating is used to coat the surface of the lock mechanism with a layer of another metal, such as nickel or brass. This can improve the appearance of the lock and also increase its wear resistance to prevent corrosion, electrical conductivity, reflectivity and aesthetics, etc. Additionally, electroplating can be used to add a layer of a different metal that provides additional security features, such as increased resistance to picking or drilling.

Process Flow

Pretreatment → cyanide-free alkaline copper → cyanide-free white copper tin → chrome plating

Advantages: 1. High gloss of plating layer, high quality metal appearance.

2、Substrate material is SUS, Al, Zn, Mg, etc.; cost is low relative to PVD.

Disadvantages: poor environmental protection and with higher risk of environmental pollution.

Powder Spraying

Powder coating is a method of applying a protective and decorative finish to metal surfaces, such as door locks. In this process, a fine powder made of resin and pigments is electrostatically applied to the surface of the lock. The powder is then heated to a high temperature, causing it to melt and fuse together, creating a hard, durable finish. Powder coating can provide a variety of benefits for smart door locks, including improved durability, corrosion resistance, and aesthetic appeal. Additionally, powder coating is a relatively environmentally friendly process, as it produces fewer emissions than traditional liquid painting methods.

Process Flow

Put on door lock material → electrostatic dust removal → spraying → low temperature leveling → baking

Advantages

1、Rich colors, high gloss and matte optional.

2、Lower cost, suitable for architectural furniture products and heat sink’s shell, etc.;

3、High utilization rate, 100% utilization, environmental protection.

4、Strong ability to cover defects.

5、Can imitate the wood grain effect.

Disadvantages

currently used for electronic products is relatively small.

Metal Drawing

It is a surface treatment means to form a line pattern on the surface of door locks by grinding the product to play a decorative effect. According to the different patterns after wire drawing, it can be divided into: straight wire drawing, messy wire drawing, corrugation, and spin.

The wire drawing treatment can make the metal door lock surface obtain a non-mirror-like metallic luster, and at the same time, the drawing treatment can also eliminate the subtle defects on the metal surface.

Sandblasting

It is a process that uses compressed air as the power to form a high-speed jet beam to spray material at high speed onto the surface of the door lock to be treated, so that the appearance or shape of the door lock outer surface of the work piece changes and a certain degree of cleanliness and different roughness is obtained.

Technical Characteristics

1、To achieve different reflective or matte.

2、It can clean the tiny burrs on the surface of workpiece and make the surface of workpiece more flat, eliminate the harm of burrs and improve the grade of workpiece.

3、Clear the residual dirt left behind during pre-treatment, improve the finish of the workpiece, can make the workpiece reveal uniform and consistent metal original color, make the appearance of the workpiece more beautiful and good-looking .

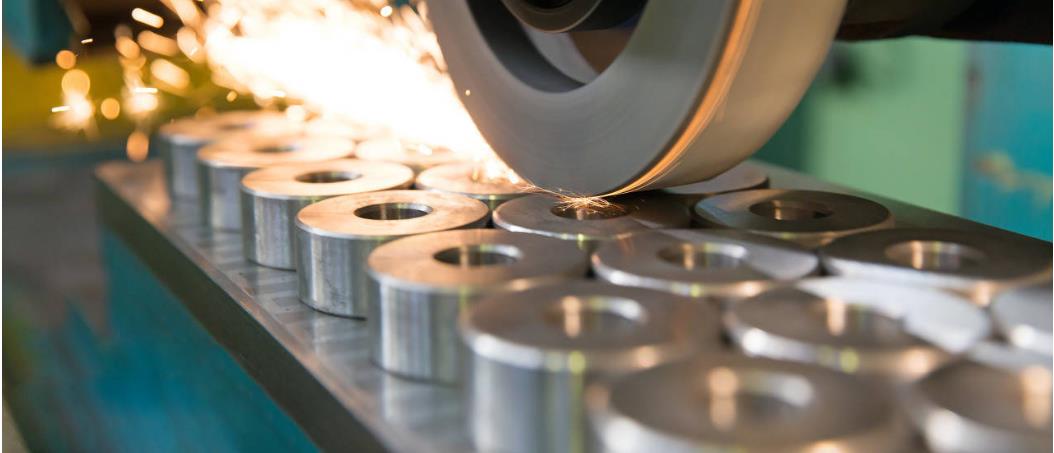

Polishing

The finishing process of the workpiece surface using flexible polishing tools and abrasive particles or other polishing media. For different polishing processes, there are: rough polishing (basic polishing process), medium polishing (finishing process) and fine polishing (varnishing process), choosing the right polishing wheel can achieve the best polishing effect and improve the polishing efficiency at the same time.

Polish can improve the dimensional accuracy or geometric shape accuracy of the workpiece, get a smooth surface or mirror shine, and also eliminate the shining on door lock surface, polished surface is simple and generous.

Etching

Etching, also known as photochemical etching, refers to the exposure of the plate, after the development, to remove the protective film of the etched area, in contact with the chemical solution during etching, to achieve the effect of dissolution corrosion, the formation of concave and convex or hollow molding effect.

Process flow

Exposure method: engineering according to the graphics open the size of the preparation – material preparation – material cleaning – drying → film or coating → drying → exposure → development → drying – etching → de-filming → OK

Screen printing method: open material → cleaning plate (stainless steel other metal materials) → screen printing → etching → de-filming → OK

Advantages

1、The metal surface can be finely processed;

2、Giving the metal surface special effects.

Disadvantages

Most of the corrosive liquids (acid, alkali, etc.) used in etching are harmful to the environment.

For smart door locks, the main surface treatment always adopt are: Anodic oxidation, Micro-arc oxidation, PVD Vacuum Deposition, Electroplating, Powder Spraying, Metal drawing, Polishing, different material and use for different place, will adopt the different treatment consider lock durability and appearance.